Model 5650 Single Blade Type

Features

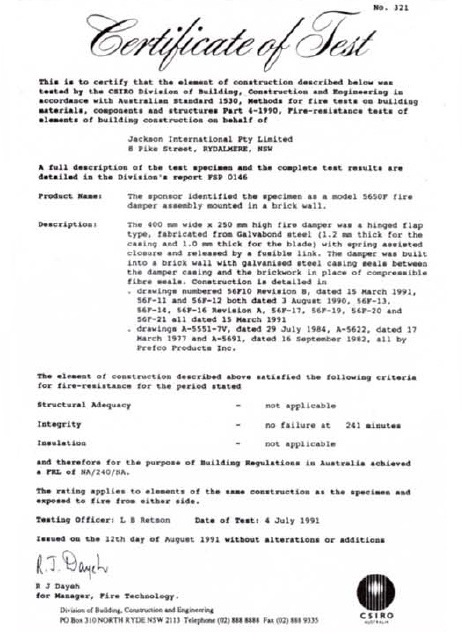

- Australian certified to AS1682.1 – 1990 by the CSIRO in:

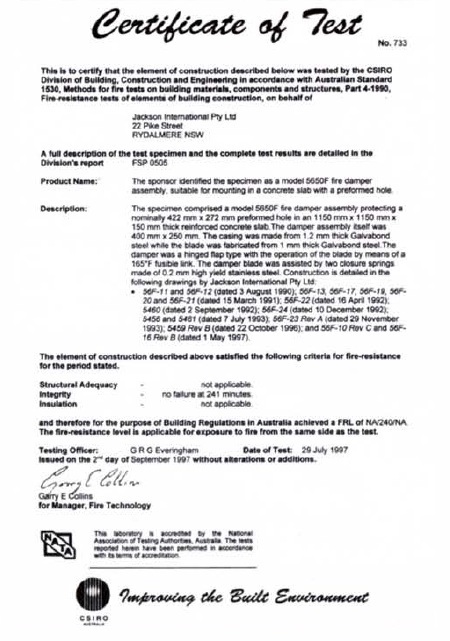

- Masonry walls for 4 hours. Test #- FSP-0145, FSP-0146

- Concrete slabs for 4 hours. Test #- FSP-0505

- Steel Stud Plasterboard partition for 2 hours. Test #- FSV-0100

- Non-loadbearing vent shaft patition (48mm) for 2 hours. Test #-FSV-0538

- Optional Airflow tested by the CSIRO for blade closure in excess of 8m/s. Test #- FS2946/1558

- Single hand reset from either side

- Approved UL33 fusible link (165oF – 74oF) in closed hook for easy replacement (no tools)

- Light-weight construction without welding ensures the integrity of the damper’s galvanized coating

- Side blade closure dampers available for specific building applications

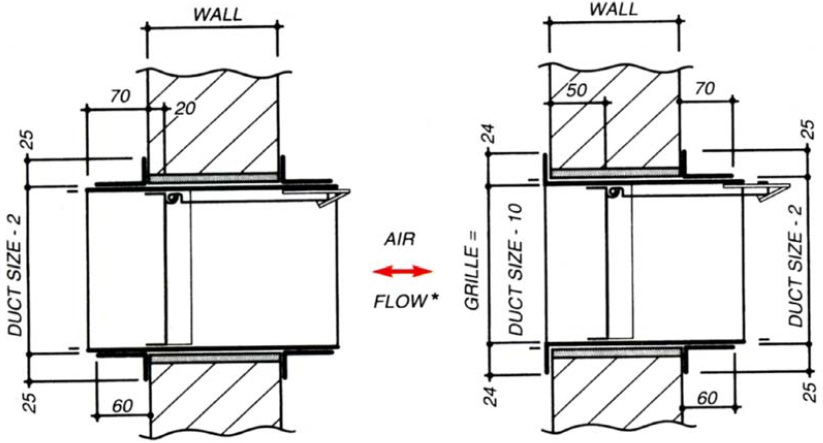

- Duct to Duct (D) and Dut to Grille (GS) configurations in sizes 100mm x 100mm up to 400mm to 250mm available at short notice

The body style ‘GS’ is the same outside dimensions as Style ‘D’. Grilles or Registers will need to fit in a clear opening 10mm less than nominal seize. (Example: Nominal 200 x 200 will have a clear opening of 190 x 190. *Refer blade closure against the airflow test for optional airflow direction rates (Blade Closure)

Permissible air leakage test number 323

n the closed blade position, Bullock Model 5650 Drop Lock type fire damper passes the permissible air leakage test with flying colours! No other fire damper of it’s kind comes close. The double action stainless steel spring with blade dimples provides a positive low leakage shut off.

Blade closure against airflow test

CSIRO testing shows that the 5650 fire damper blade closes at the following. (Test #- FSZ-0522)

Size 150 x 150 = 11.0 m/s*

Size 200 x 200 = 18.0 m/s*

Size 250 x 250 = 19.0 m/s*

Size 400 x 250 = 16.5 m/s (Double Spring)*

Size 400 x 250 = 10.0 m/s (Single Spring)

*Maximum speed at which Bullock test blower was capable of as per damper size*

Installation

Compliance with installation is critical. Refer to separate installation instructions to suit your application, all mechanical fire dampers require expansion gaps

Maintenance

This model requires little maintenace once installed. Refer to AS1851.6-1997 for detailed servicing procedures.

Test certificates (slab wall)

Metal expansion gap spacers

Metal gap spacers allow damper to be installed insitu with a controlled expansion gap.

- No installation costs

- No hazardous fibers

- Factory set expansion gap

Maintenance

This damper requires little maintenance once installed, refer to AS1851.6-1997 for detailed maintenance procedures.