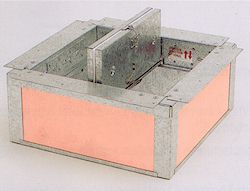

Model 5691A Ceiling / Radiation Assembly

Model 5691 Ceiling Radiation Damper

Plenum / Spigot

Features

- Australian certified to AS1530.4-1997 by the C.S.I.R.O.- Test #FS3033/1516

- Optional Airflow tested by the C.S.I.R.O. for blade closure in excess of 18m/s – Test #FS3099/1961

- All galvanised steel construction

- Structurally strong ‘C’ shaped centre pivot

- Incorporates a high yield 2mm stainless steel spring(s)

- Single (UL33 rated) fusible link located for quick response to temperature rise

- Heat resistant 13mm high density ceramic fibre board blade insulation

- Readily available square and rectangular sizes from 150mm x 150mm up to 600mm x 600mm

Installation

Compliance with installation instructions is critical. Refer to separate instructions for specific PLASTERBOARD fire rated ceiling system used.

Maintenance

This model damper requires little maintenance once installed. Refer to AS1851-2012 for detailed servicing procedures.

Typical Specifications

Openings in Ceilings are required to have an FRL, shall be protected by a BULLOCK MODEL 5691 CEILING RADIATION/FIRE DAMPER or approved equivalent

The dampers shall be provided where shown on drawings and wherever required to meet local regulations and MUST comply with AS1682.1-2015.

Dampers shall be mounted in strict accordance with the manufacturer’s installation instructions, to comply with the Certificates of test furnished by the manufacturer.

The damper construction must be in compliance with the tested prototype containing features as: High yield stainless steel spring(s), four corner blade locking for positive closure to achieve low air/smoke leakage. Dampers installed in return air or exhaust applications must be capable of operation, at airflow rates in excess of the actual design application. (NOTE: Model 5691 dampers have a certified closure rating of 18m/s). Radiant heat effect from the face of the damper and leakage of hot gasses must be reduced to maintain uninsulated metal duct surface temperature directly above the damper to below 150°c after 120 mins exposure. Blades must easily be reset from the underside for testing and maintenance in accordance with AS1851.2012.